Why Is the AC Tubular Motor Becoming the Preferred Choice for Automated Shading and Industrial Lifting Systems?

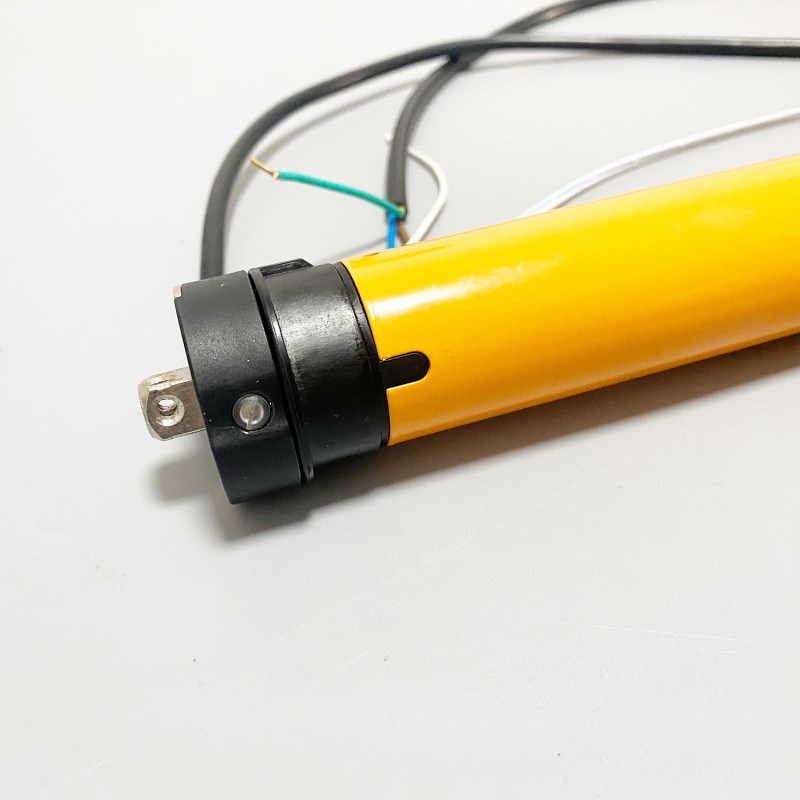

An AC tubular motor is a compact, high-torque electric drive designed to fit inside cylindrical tubes, enabling automated lifting, rolling, or rotating functions in a wide range of shading, industrial, and architectural systems. Its cylindrical shape allows seamless installation within roller blinds, awnings, shutters, projection screens, conveyor tensioners, and commercial lifting devices. The combination of durability, stable AC power, and efficient torque distribution makes the AC tubular motor a foundational component of modern building automation and industrial equipment.

Key Technical Parameters of AC Tubular Motors

| Parameter Category | Specification Details |

|---|---|

| Rated Voltage | AC 110V / 220V / 230V / 380V (customizable per region) |

| Frequency | 50Hz / 60Hz |

| Power Range | 60W – 400W depending on motor type |

| Torque Output | 10Nm – 300Nm for varied lifting demands |

| Motor Diameter Options | 35mm / 45mm / 59mm / 92mm / 120mm tubes |

| Running Speed | 12rpm – 30rpm for standard shading systems; higher rpm available for industrial variants |

| Insulation Class | Class E / Class B depending on model |

| Protection Level | IP44 / IP54 dust and splash protection |

| Control Options | Manual switch, remote control, group control, timer control, intelligent automation, wired and wireless options |

| Thermal Protection | Automatic shutdown to prevent overheating |

| Noise Level | Low-noise operation suitable for residential interior use |

| Application Compatibility | Roller shutters, blinds, screens, awnings, light-duty industrial lifting, conveyor tension systems |

These parameters demonstrate the versatility and engineering sophistication of AC tubular motors, which are valued for their balance of size, strength, and user-friendly configuration options.

Why Are AC Tubular Motors Increasingly Used Across Residential, Commercial, and Industrial Applications?

The adoption of AC tubular motors has surged because they deliver a combination of strength, durability, and long-term reliability unmatched by most DC-powered alternatives. The design inherently supports large lifting loads while maintaining consistent torque output, making them suitable for daily operation even under demanding conditions.

Why Businesses and Homeowners Prefer AC Tubular Motors

1. High Torque Output for Demanding Loads

AC tubular motors offer significantly higher torque than similar-sized DC motors, making them ideal for large roller shutters, oversized blinds, heavy commercial screens, and industrial lifting systems. Their torque stability ensures smooth and uniform movement even after years of operation.

2. Long Service Life With Minimal Maintenance

The internal construction uses durable gears, insulated windings, and thermal protection systems designed to withstand long operating hours. Maintenance demands remain minimal compared with chain-driven or hydraulic lifting systems, making them cost-effective over time.

3. Compatibility With Modern Automation Technologies

Building automation continues to evolve, and AC tubular motors are designed to integrate seamlessly with:

– Smart home platforms

– Automated lighting and shading systems

– Group-control building management systems

– Wired and wireless central controllers

Their adaptability makes them ideal for homes, offices, hotels, schools, and industrial facilities.

4. Safety and Stability in Continuous Use

Thermal protection, overload defense, and stable AC current provide consistent performance even during extended periods of operation. These safety features are especially important for commercial shutters, exterior awnings, and industrial lifting applications.

5. Silent Operation Suitable for Interior Environments

The optimized internal gear structure produces low operational noise, supporting comfortable use in bedrooms, meeting rooms, classrooms, and hotel environments where silent automation is preferred.

6. Versatility Across Industries

AC tubular motors support a wide portfolio of applications:

– Residential roller blinds

– Garage doors

– Exterior sun-shading awnings

– Commercial roller shutters

– Projection screens

– Factory conveyor tensioners

– Ventilation system dampers

The ability to adapt the motor diameter, torque output, and control system makes it a universal automation solution.

How Do AC Tubular Motors Deliver Operational Efficiency, User Convenience, and Future-Ready Functionality?

Understanding how AC tubular motors function sheds light on why they are becoming the backbone of numerous architectural and industrial solutions.

How AC Tubular Motors Operate

AC tubular motors use electromagnetic induction to create rotational force. The rotor spins within the cylindrical housing, driving a gear set connected to the tube mechanism. The internal limit-switch structure accurately controls the opening and closing positions, preventing over-rotation and ensuring consistent mechanical alignment.

The linear and symmetric design ensures efficient force transfer, allowing for:

– Smooth rotation

– Minimal vibration

– Low heat generation

– Long mechanical lifespan

How They Improve Efficiency for Users

Enhanced Energy Efficiency

AC motors convert electrical input into rotational motion with high efficiency. Their simple structure minimizes energy loss, making them more efficient for frequent or continuous operation.

Consistent Torque Under Load

Heavy shading systems, commercial shutters, and industrial rolling systems require a motor that maintains torque even under maximum load. AC tubular motors are engineered for high reliability under demanding weight and frequency conditions.

Automated Limit System for Precision

Accurate electronic or mechanical limit control ensures:

– Perfect alignment

– Avoidance of over-travel

– Stable long-term performance

This mechanism prevents mechanical stress and extends the operational life of the shading or lifting system.

How They Support Smart Control and Automation

Modern buildings are shifting toward intelligent automation. AC tubular motors support this transition through:

– Integration with wireless receivers

– Group control systems for multi-window buildings

– Timer-based opening and closing

– Sunlight and temperature-sensor automation

– Smart home ecosystem compatibility

These features help optimize natural light, enhance energy efficiency, and improve user comfort.

How They Align With Future Market Trends

The future of automated building systems emphasizes:

-

Energy conservation and sustainable architecture

-

Widespread smart home adoption

-

Demand for durable, low-maintenance mechanisms

-

Greater user convenience through remote and automated control

-

Expansion of large-format shading in commercial properties

AC tubular motors directly support these trends with their durable structure, high torque capability, and ease of integration with intelligent control systems.

In the industrial sector, AC tubular motors are expected to be widely used in automated shutoff devices, conveyor systems, and storage-lift systems due to their excellent torque stability and long-lasting performance. Their adaptability to harsh operating environments makes them a key component in industrial automation expansion.

What Are the Most Common Questions About AC Tubular Motors? (FAQ)

Q1: How long can an AC tubular motor typically operate before maintenance is required?

A: AC tubular motors are engineered for long service life through the use of durable internal gear structures, fully insulated windings, and protective thermal systems. Most motors can operate for 10,000 to 15,000 cycles before any maintenance is required under normal conditions. When used in commercial settings with higher frequency cycles, periodic inspection of the tube mechanism and limit system is recommended. However, the motor itself typically requires very little intervention due to its sealed design and minimal mechanical friction.

Q2: What factors should be considered when selecting the right AC tubular motor for a project?

A: Choosing the correct tubular motor involves evaluating multiple factors:

– Lifting load or shading size to determine required torque

– Roller tube diameter compatibility

– Operation frequency for selecting appropriate thermal performance

– Control method preferences, such as remote control, switch control, wired automation, or smart home integration

– Environmental conditions, including humidity or dust levels influencing IP protection grade

– Installation location, especially if large-format systems or exterior awnings require higher torque ranges

By assessing these elements, users can select a motor that ensures optimal performance, long-term reliability, and user convenience.

The Growing Importance of Reliable AC Tubular Motors

AC tubular motors are becoming essential components in both residential and industrial automation due to their compact structure, consistent torque, durability, and compatibility with intelligent control systems. They offer reliable automation for shading, lifting, and rolling mechanisms while supporting the global trend toward energy-efficient and smart building solutions. The continuous technological development within the field suggests that AC tubular motors will remain central to innovation in architectural automation and industrial mechanical systems.

As the market demands higher performance and long-lasting automation solutions, FT Motor continues to provide advanced AC tubular motor products designed for stability, efficiency, and long-term durability. For project consultation, product details, or customized solutions, contact us to receive professional support tailored to your application needs.